Technical InformationTensile Creep Test

Tensile creep characteristics under constant load

Tensile Creep Test

(1) Purpose

When a constant load is continuously applied, strain increases (creep phenomenon).

The creep phenomenon becomes particularly strong at higher temperatures.

The tensile creep characteristics must then be determined as design indicators.

(2) Test conditions

| Test item | Tensile creep strain, rupture time |

|---|---|

| Sample shape | JIS K7161-2 Type-1B dumbbell shape |

| Measuring conditions | Distance between chucks: 115 mm Initial strains: present Note: Strains present before the full load was applied were verified using a universal testing system for their strength, and the creep test result was adjusted accordingly. |

| Test temperature | 40°C, 80°C, and 100°C |

| Test stress | Calculated and set as 20%, 40%, and 60% of the tensile strength at each temperature. |

| Number of hours tested | Maximum of 1,000 hours |

| Test machine | Universal Testing System—Model 5982 for initial strain verification (manufactured by Instron) Universal Creep Tester—1,000 kgf model (manufactured by DJK Corporation) Displacement Transducer DTH-A-30 (manufactured by Kyowa Electronic Instruments) |

(3) Result

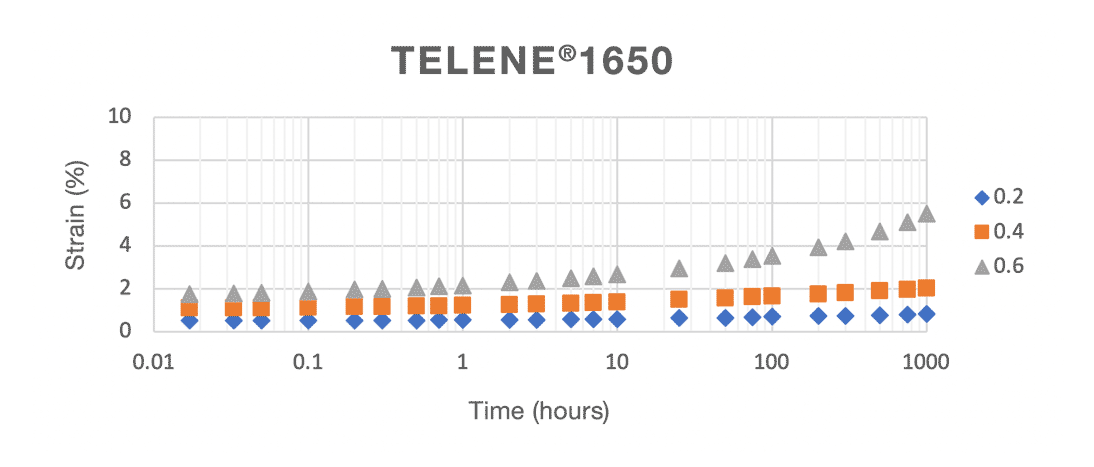

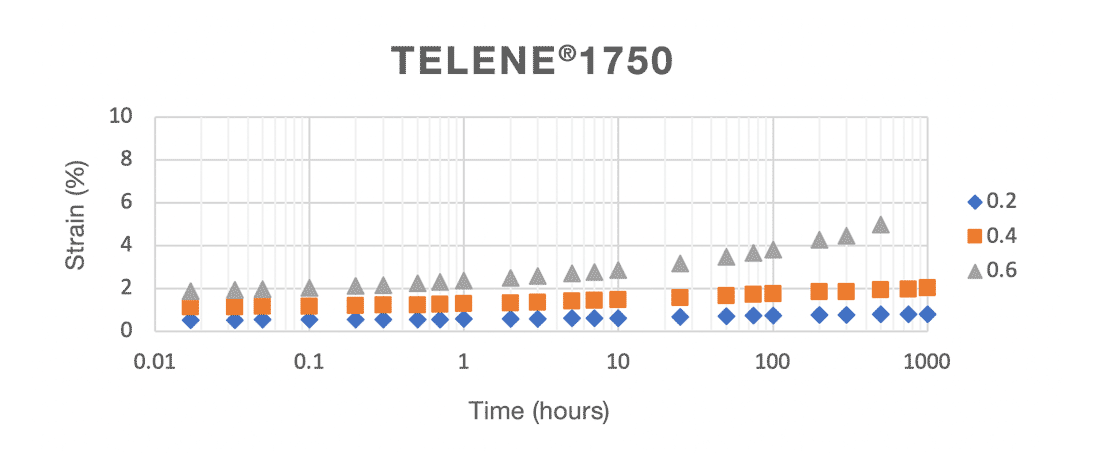

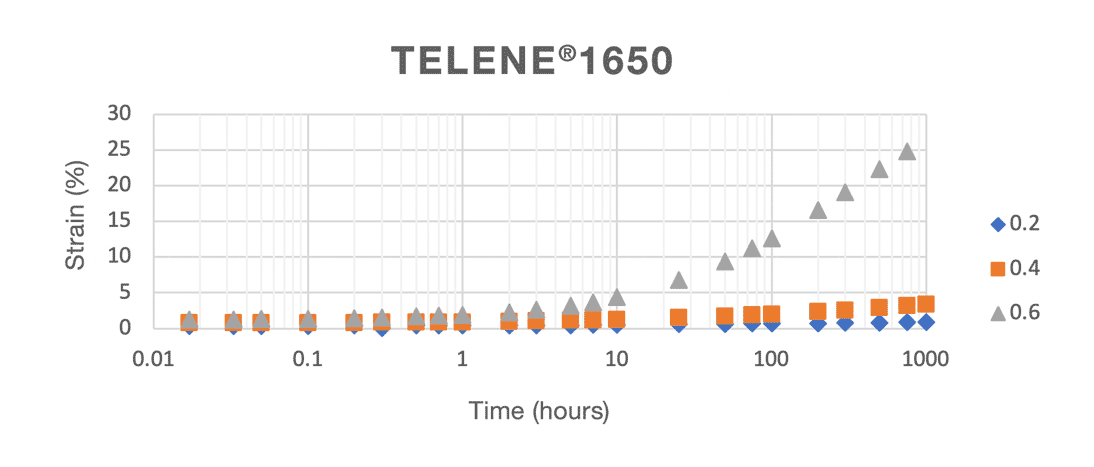

40℃

At 40°C, no rupture occurs even under a load of 60% of rupture stress after 1,000 hours.

Under a load of 40% of rupture stress, 2% creep strain occurs after 1,000 hours.

Under a load of 20% of rupture stress, 0.8% creep strain occurs after 1,000 hours.

Rupture occurred after about 720 hours at 40°C, under a load of 60% of rupture stress.

Under a load of 40% of rupture stress, 2% creep strain occurs after 1,000 hours.

Under a load of 20% of rupture stress, 0.8% creep strain occurs after 1,000 hours.

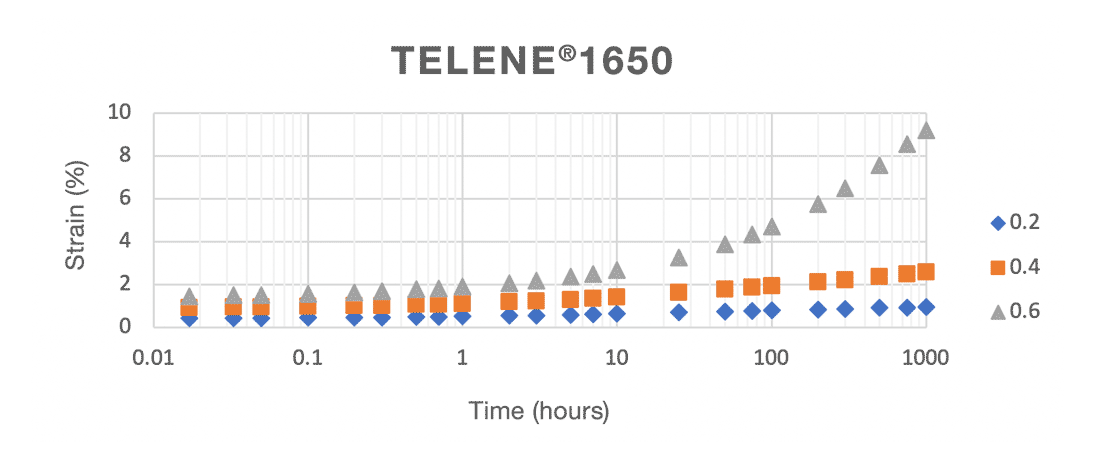

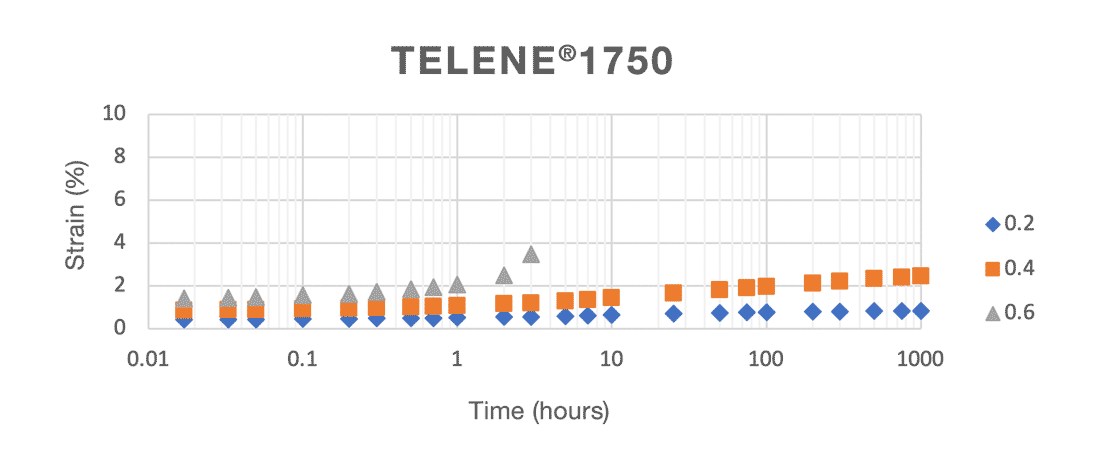

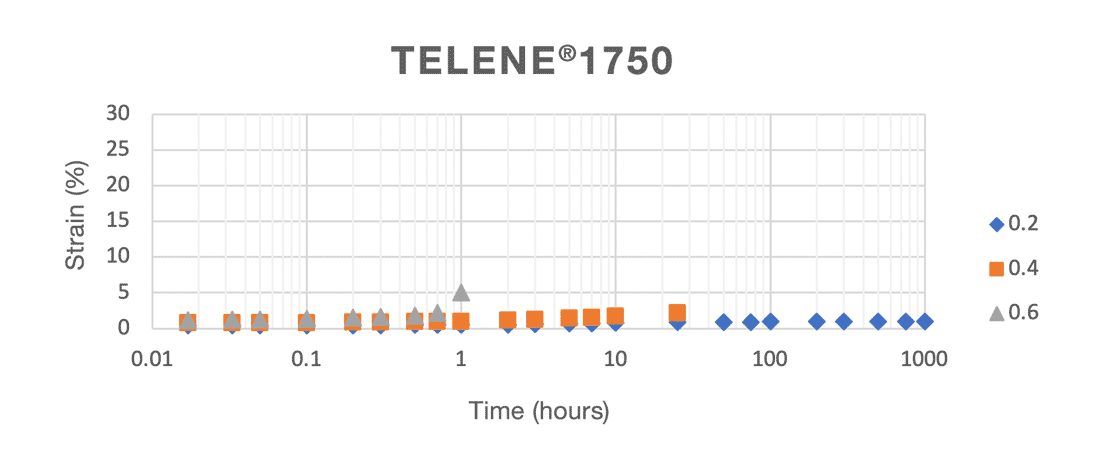

80℃

Under a load of 60% of rupture stress, 9% creep strain occurs after 1,000 hours.

Under a load of 40% of rupture stress, 2.6% creep strain occurs after 1,000 hours.

Under a load of 20% of rupture stress, 1% creep strain occurs after 1,000 hours.

Under a load of 60% of rupture stress, it ruptured after about 3.7 hours.

Under a load of 40% of rupture stress, 2.5% creep strain occurs after 1,000 hours.

Under a load of 20% of rupture stress, 0.8% creep strain occurs after 1,000 hours.

100℃

Under a load of 60% of rupture stress, it ruptured after about 830 hours.

Under a load of 40% of rupture stress, 3.3% creep strain occurs after 1,000 hours.

Under a load of 20% of rupture stress, 0.9% creep strain occurs after 1,000 hours.

Under a load of 60% of rupture stress, it ruptured after about 1 hour.

Under a load of 40% of rupture stress, it ruptured after about 30 hours.

Under a load of 20% of rupture stress, 1% creep strain occurs after 1,000 hours.