Intended Uses and ApplicationsIndustrial Applications

Industrial enclosures that are large and strong are generally made of metal.

PDCP has been widely adopted as an alternative material for such enclosures since it can be molded into large, thick-walled shapes and is corrosion resistant and light.

Because of these properties and lowers costs in terms of installation and related expenses, there is a lot of potential for this resin’s use in other applications.

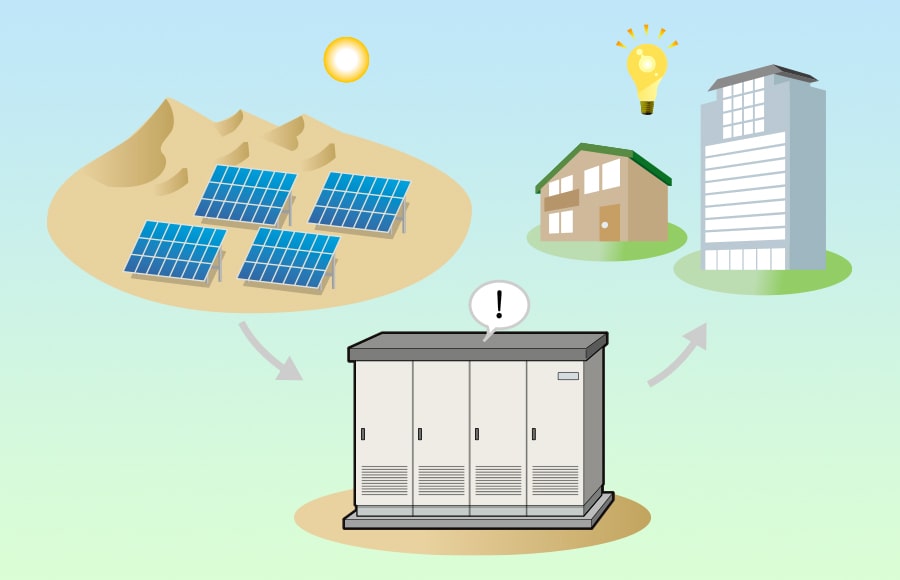

Example Application OneExternal Enclosures for Power Conditioners

Reasons

- High impact strength

- Lower installation cost due to its lightweight

- Improved handling due to its lightweight

- High degree of design flexibility (easily accommodates openings and streamlined shapes)

- Significant economic benefits (molding equipment costs less than that for other molding methods)

- Easy to join and paint (easy to join assembly parts)

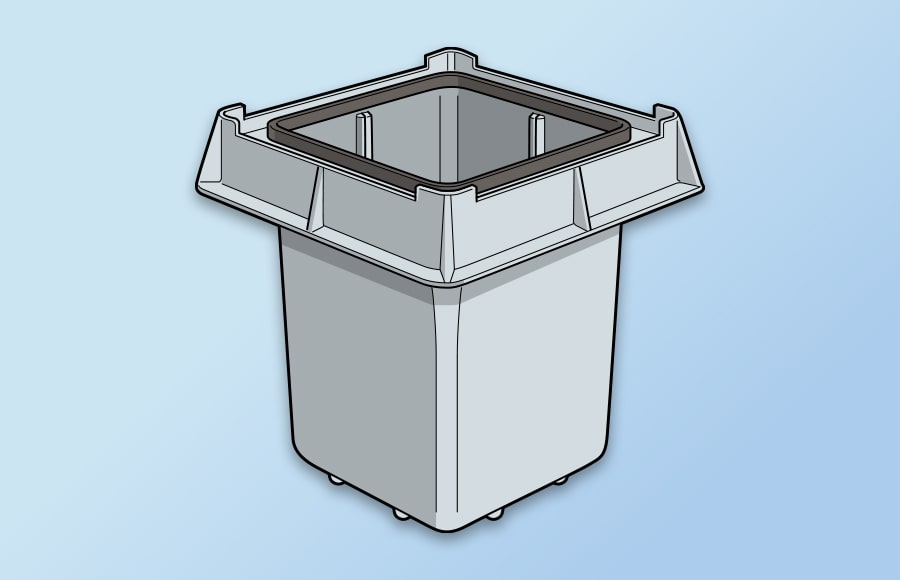

Application Example twoBuried Power Boxes

Reasons

- High impact strength

- High degree of design flexibility (easily accommodates openings and streamlined shapes)

- Significant economic benefits (molding equipment costs less than that for other molding methods)

- Easy to join and paint (easy to join assembly parts)

- Lightweight

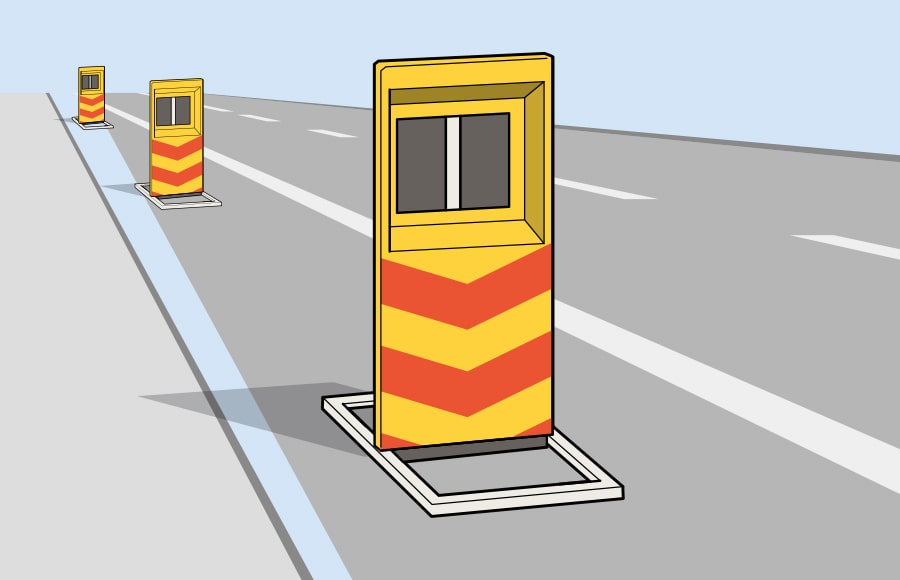

Example Application ThreeOutdoor Speaker Enclosures

Reasons

- High impact strength

- High degree of design flexibility (easily accommodates openings and streamlined shapes)

- Significant economic benefits (molding equipment costs less than that for other methods)

- Easy to join and paint (easy to join assembly parts)

- Lightweight