Technical InformationMolding Technology

Molding process for TELENE®1800 series

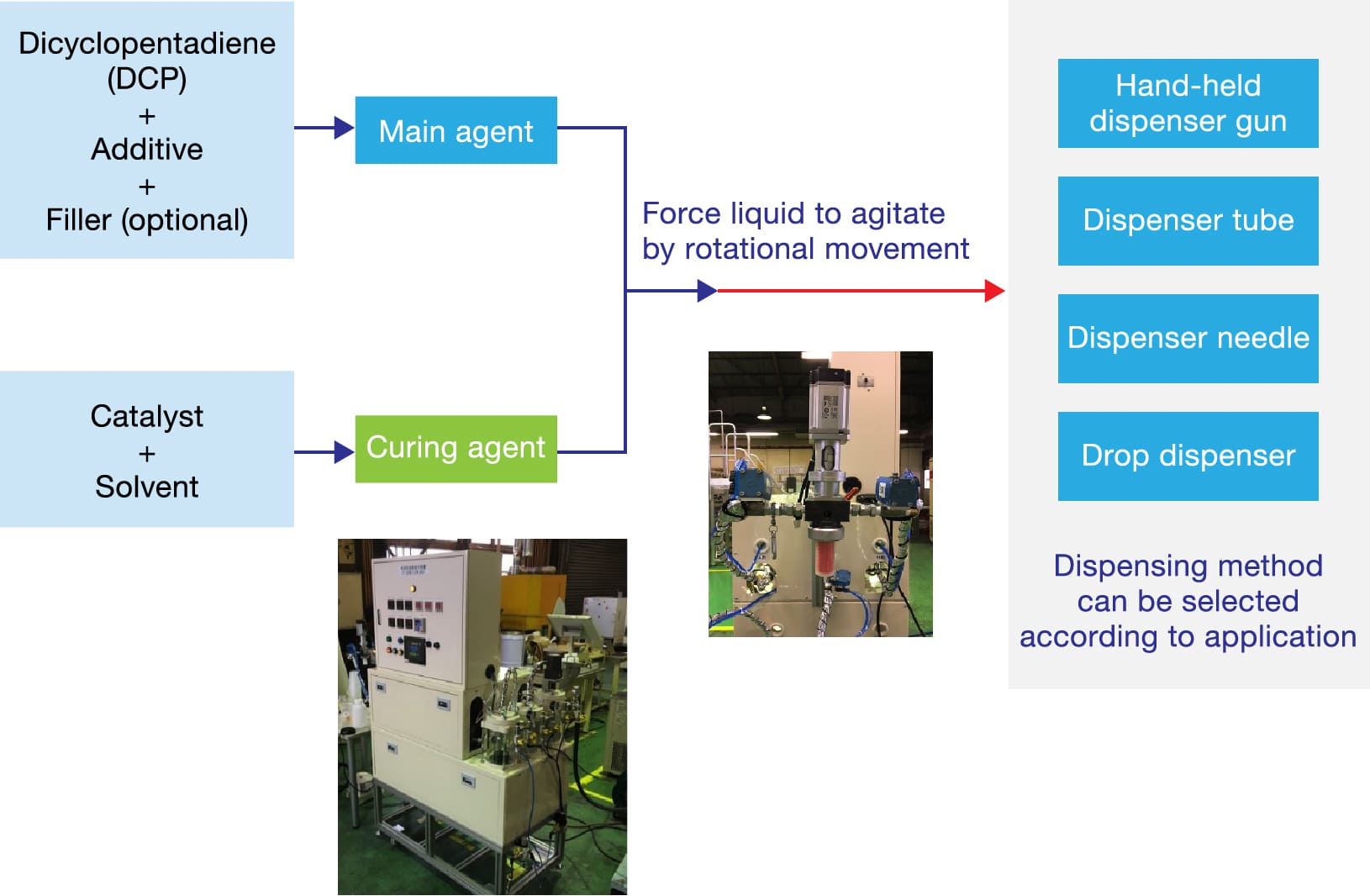

Because of the major gap in the main agent to the curing agent mixture ratio of TELENE®1800 series, the mixture needs to be agitated using rotational forces to be blended. After agitation, the mixture is poured into molds using a suitable dispensing method and then shaped into products.

Because the main agent of TELENE®1800 series is primarily composed of dicyclopentadiene (DCP), which has a low viscosity, it can be added with large amounts of inorganic filler. This means that specific features, such as a lower linear expansion coefficient and higher thermal conductivity, can be applied to resins.

The curing time of TELENE®1800 series is temperature-dependent and therefore curing time can be adjusted by controlling the temperature when weighing and mixing the compounding liquids.

RIMTEC has developed a specialized automatic measuring and mixing system that takes advantage of TELENE®1800 series’s properties. We are continually developing new technologies so we can propose holistic solutions that include the manufacturing processes when customers introduce our products.

Application for the Low-viscosity of TELENE®1800 series (simulated coil sealing)